High purity microcrystalline alumina ceramic powder series

Classification:

High purity microcrystalline alumina ceramic powder series

E-mail:

Details

Product Characteristics:

Aluminum oxide micro-powder features high purity, small particle size, narrow particle size distribution, good dispersibility, stable process, consistent batch performance, and excellent low-temperature sintering properties. High-purity aluminum oxide ceramic powder supports micro-customization of properties, allowing for adjustments according to customer requirements to provide more personalized product services.

Model parameters:

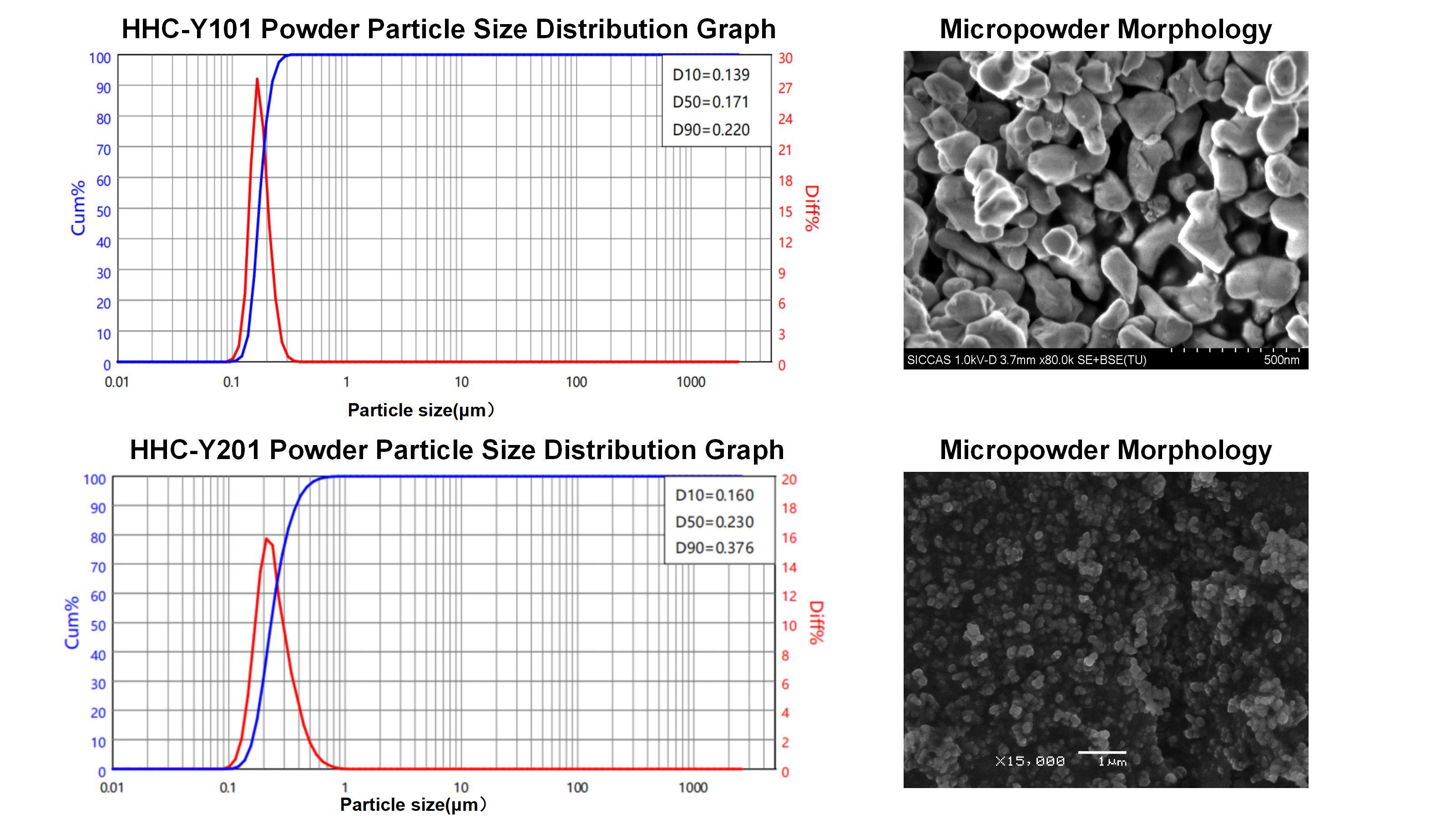

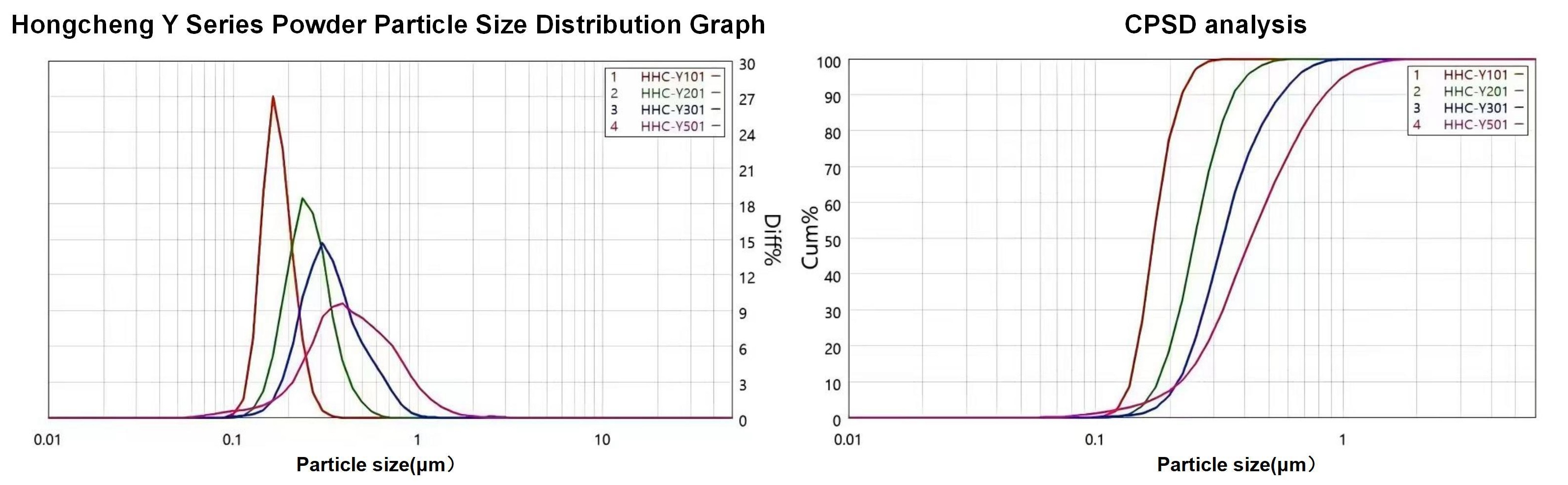

product model | units | HHC-Y101 | HHC-Y201 | HHC-Y301 | HHC-Y501 | HHC-YM501 | |

purity | % | ≥99.99 | |||||

a-Phase conversion rate | % | >93 | |||||

BET specific surface area | m2/g | 13-15 | 9-12 | 6-9 | 4-7 | 4-7 | |

apparent density | g/cm3 | 0.6-0.9 | |||||

moisture content | % | 0.5±0.1 | |||||

ignition loss | % | 0.15±0.05 | |||||

median particle diameter | μm | 0.170±0.01 | 0.250±0.01 | 0.350±0.01 | 0.500±0.05 | 0.500±0.05 | |

impurities | Na | ppm | ≤3 | ||||

Fe | ppm | ≤3 | |||||

Si | ppm | ≤20 | |||||

Ca | ppm | ≤1 | |||||

K | ppm | ≤3 | |||||

Mg | ppm | ≤3 | 300~1000ppm customized | ||||

Application Fields:

1、As an abrasive material, it is used to manufacture various wear-resistant parts, such as sand blasting nozzles, abrasive balls, conveying pipelines, etc. It has excellent wear resistance and impact resistance, which can greatly improve the service life and production efficiency of equipment. It has excellent wear resistance and impact resistance, which can greatly improve the service life and production efficiency of the equipment.

2、Widely used in ceramic crafts, ceramic tiles and other manufacturing.

3、In electronic materials, it can be used to make high purity alumina ceramic substrate. Due to its high purity and good sintering performance, the substrate has excellent electrical insulation, high thermal conductivity and dimensional stability, can provide stable support for electronic components and good heat dissipation performance, widely used in integrated circuits, power modules, LED lighting and other electronic equipment.

4、In the field of catalyst, it can provide high specific surface area, increase the reaction activity, and thus improve the catalytic effect.

5, In the bioceramics, high-purity alumina ceramics have good biocompatibility and biological inertia, good compatibility with human tissues, will not cause immune response and rejection. It can be used to make artificial joints, bones and other implants to help patients restore motor function. Can also be used to make dental restorations, such as crowns, bridges, dental implants and so on.

6, Due to high temperature resistance, high strength, high hardness and other characteristics, can be used to manufacture high-temperature structural components in the aerospace field, such as engine blades, combustion chambers, heat insulation panels.

Recommend Products

High purity low temperature sintered alumina granulation powder series

High purity low temperature sintered alumina granulation powder series

High purity low temperature sintered alumina granulation powder series

High purity low temperature sintered alumina granulation powder series

High purity microcrystalline alumina ceramic powder series

High purity microcrystalline alumina ceramic powder series

Online Message

Please enter your contact information and we will contact you as soon as possible!

Contact Us

Mr. Wang:+86-18039583172

Mr. Wu:+86-19293821515

E-mail:674189743@qq.com

E-mail:303265822@qq.com

Address: 1st Floor, Building A-07, Hangtou Aviation Manufacturing Industrial Park, No. 526 Liangzhou Avenue, Minggang Office, Zhengzhou Airport Economic Comprehensive Experimental Zone

concern us]